Welcome to Shanghai Jescale Instrument Technology Co., Ltd

Contour Measuring Instrument

Category:

Contour Measuring Instrument

Product Center

- Product Description

-

Technical Features

◆ The X-axis and Z-axis adopt independent mechanical systems, which can realize linkage measurement within the full range of X and Z axes at the same time, with a wide range of applications

◆ The X-axis and Z-axis adopt full-range high-precision grating measurement system, and the closed design can minimize wear and improve reading reliability

◆ Ultra-high precision linear guides ensure the stability of measurement data

◆ Lightweight high-strength carbon fiber polymer measuring arm with independently developed anti-collision mechanism

◆ Electronic feedback force measurement mechanism can be adjusted according to different part materials

◆ Quick clamping probe with self-positioning design

◆ Customizable single and bidirectional measurement tasks, with a wide range of application scenarios

◆ All-Chinese measurement software, rich report formats and measurement task export formats

◆ Can meet laboratory or work site use

◆ Semi-automatic measurement mode greatly reduces manual workload

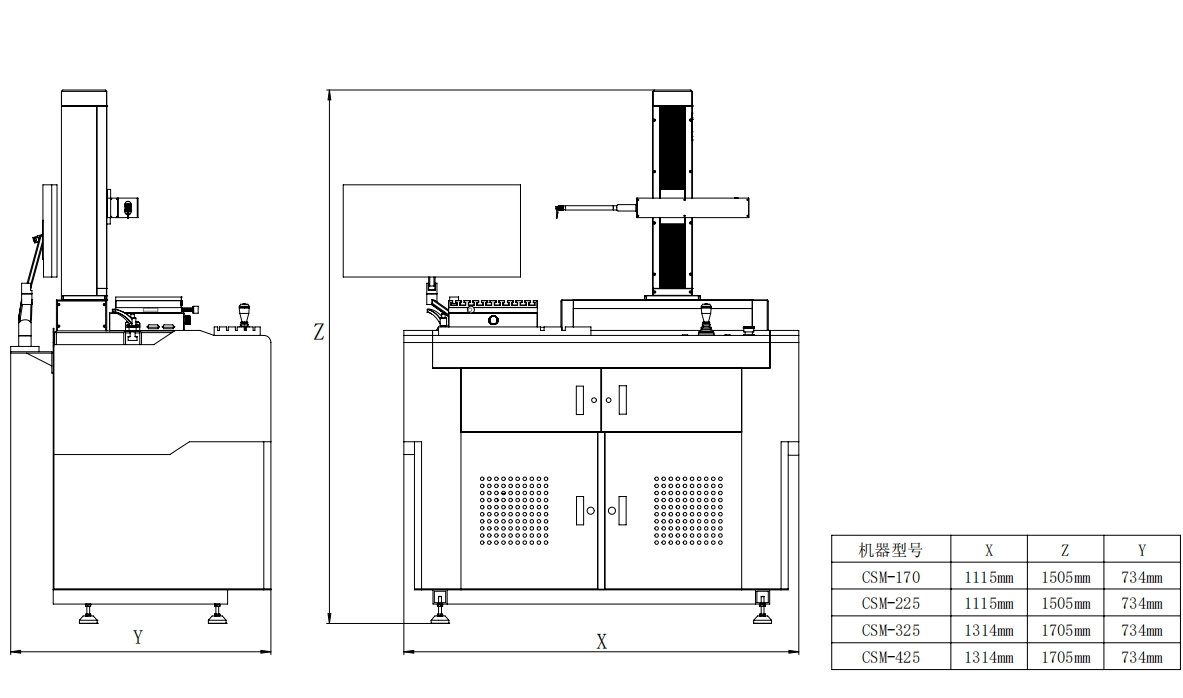

Technical Parameters

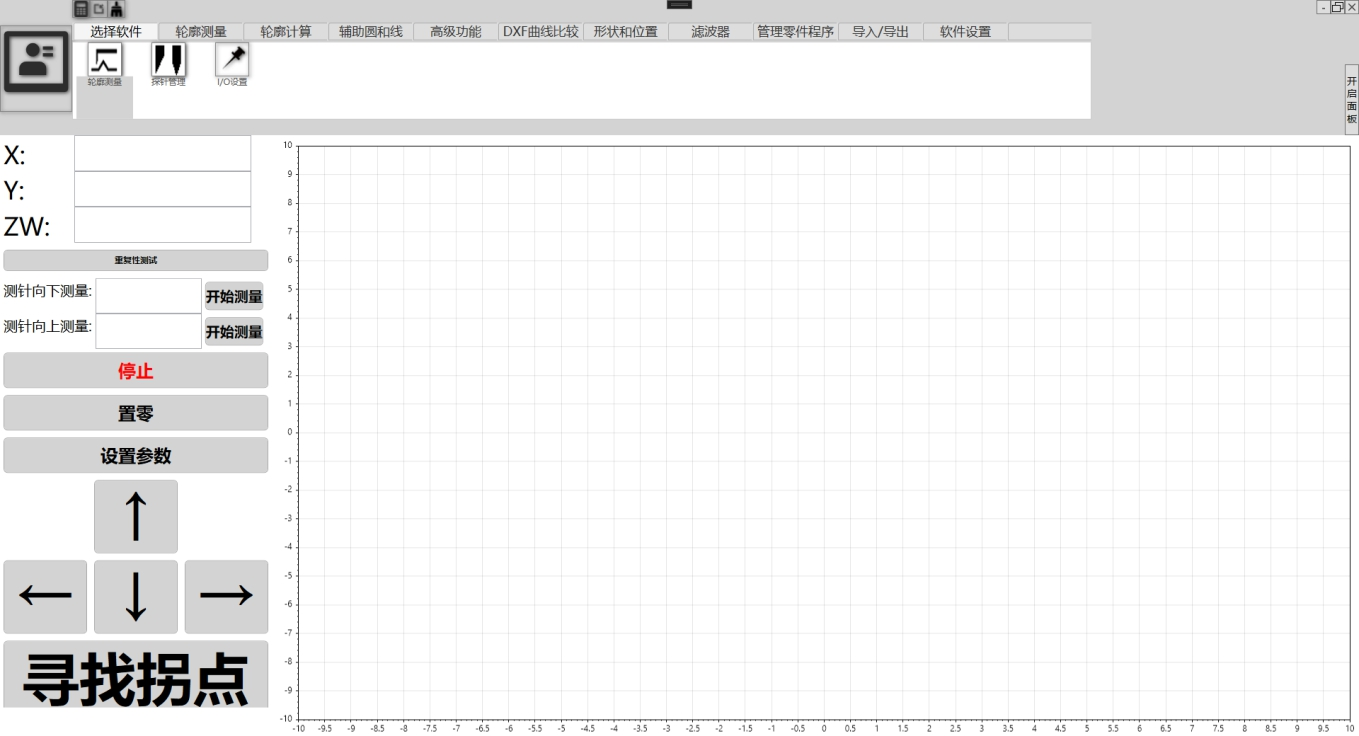

Software Testing Diagram

Bidirectional Measurement Function

Bidirectional measurement, contour, roughness and cylindricity are displayed at one time. OPTACOM roughness and cylindricity measurement software can automatically evaluate the contour of parts. Users only need to select the measurement standard, and the measurement parameters are automatically displayed without any other settings by the user. All measurement parameters comply with DIN-ISO standards. Using this function, users can save a lot of time, reduce user pressure, and avoid unnecessary errors. Moreover, through calculation, users can obtain the shape, angle, and coordinate data of the contour, which can be displayed by the software. After the user completes the evaluation of all parameters, the measurement report can be printed. The printing software module has a database, and all print data can be saved. Of course, users can choose different print formats, such as PDF, JPG, EXCEL.TXT, etc. formats are supported.Roughness Measurement Software

Measurement software calculation is fast

Evaluate profile dimensions and roughness parameters in one measurement

Measurement parameters are automatically calculated according to standards

Roughness parameters can be evaluated according to different standards

Roughness evaluation can be performed using oblique lines or circles on the contour graph.

Measurement reports can be displayed graphically or numerically

Fully automatic roughness stylus calibration

Roughness calibration is very simple

Roughness parameters conform to DIN-ISO standards

Automatic analysis and calculation of roughness numerical value

Cylindricity Measurement Module

Contour size, roughness value, and cylindricity are measured in one go.

Cylindricity measurement does not require secondary clamping, and the measurement accuracy is high.

The software automatically calibrates and aligns the part coordinate system.

Accurate and fast, large-scale rapid detection of parts.

Users can customize the measurement program.

According to the measurement program,

the contour curve of the part is quickly detected. Automatic filtering and adjustment

of evaluation parameters. Fully automatic display of

measurement results. Graphical display according to DIN ISO1101.

Customizable local error displayOptional Styli and Ordering Numbers

Order number: CSM-F-001

Tungsten steel axe stylus

Diameter 3.5mm

Length 20.5mm

Tip radius 25 μm

Angle 12°

Order number: CSM-F-002

Tungsten steel axe stylus

Diameter 3.5mm

Length 30.5mm

Tip radius 25 μm

Angle 12°

Order number: CSM-F-003

Tungsten steel axe stylus

Diameter 3.5mm

Length 30.5mm

Tip radius 100 μm

Angle 12°

Order number: CSM-F-004

Tungsten steel axe stylus

Diameter 1mm

Length 13mm

Tip radius 25 μm

Angle 19°

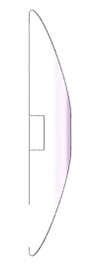

Order number: CSM-F2-001

Tungsten steel bidirectional axe stylus

Diameter 3.5mm

Length 22mm

Tip radius 25 μm

Angle 19°*2

Order number: CSM-F2-002

Tungsten steel bidirectional axe stylus

Diameter 3.5mm

Length 34mm

Tip radius 25 μm

Angle 12**2

Order number: CSM-F2-003

Tungsten steel bidirectional axe stylus

Diameter 1mm

Length 9mm

Tip radius 25 μm

Angle 19°*2

Order number: CSM-F2-004

Tungsten steel bidirectional axe stylus

Diameter 1mm

Length 10mm

Tip radius 25 μm

Angle 19°*2

Order number: CSM-Y-001

Tungsten steel cone stylus

Diameter 3.5mm

Length 59.5mm

Tip radius 25 μm

Angle 24°

Order number: CSM-Y-002

Tungsten steel cone stylus

Diameter 3.5mm

Length 33mm

Tip radius 25 μm

Angle 24°

Order number: CSM-Y-003

Tungsten steel cone stylus

Diameter 1mm

Length 59.5mm

Tip radius 25 μm

Angle 24°

Order number: CSM-Y-004

Tungsten steel cone stylus

Diameter 3.5mm

Length 33mm

Tip radius 25 μm

Angle 24°

Order number: CSM-Y-005

Tungsten steel cone stylus

Diameter 1mm

Length 9mm

Tip radius 25 μm

Angle 24°

Order number: CSM-Y-006

Tungsten steel cone stylus

Diameter 1mm

Length 20.5mm

Tip radius 25 μm

Angle 24°

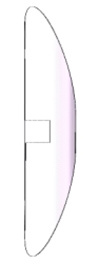

Order number: CSM-Y2-001

Tungsten steel bidirectional conical stylus

Diameter 3.5mm

Length 25mm

Tip radius 25 μm

Angle 24°

Order number: CSM-Y2-002

Tungsten steel bidirectional conical stylus

Diameter 1mm

Length 9mm

Tip radius 25 μm

Angle 24°

Function Application and Examples

Measuring plug gauge

Measuring block

Measuring ball screw

Measuring gauge

RELATED PRODUCTS

Get a Free Quote

Our representative will contact you soon.