Welcome to Shanghai Jescale Instrument Technology Co., Ltd

Contact hotline: Mr. Tang: 13120738218 Mr. Gao: 15898107995

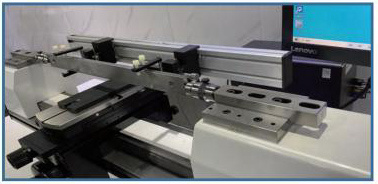

UCK Length Measuring Machine

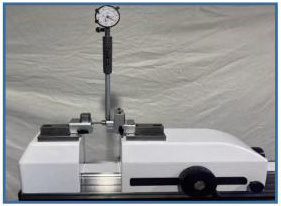

The workbench can slide and lock freely along the X-axis direction of the instrument guide rail. It is convenient to adjust the clamping and measure various length measuring tools such as: gauge blocks, smooth (threaded) ring plug gauges, calibrators, calibration rods, rulers, and meters. The calibration efficiency is extremely high and the users are extensive.

Category:

Precision Length Measuring Machine

- Product Description

-

Technical features

◆ Full-range absolute measurement to improve detection efficiency

◆ The base is made of QT450 cast iron or marble, which is stable and reliable

◆ Grating scale length: full range

◆ X-shaped base structure can effectively resist stress

◆ Resolution: 0.01μm

◆ Measuring force: Electronic force measurement 0-12N, continuously adjustable

Absolute measurement throughout

The UCK series length measuring instruments are equipped with zero expansion high-precision grating rulers throughout the entire measuring range, which reduces the impact of temperature changes on the instrument!

At the same time, it can achieve full-range absolute measurement within the entire instrument range, greatly improving the measurement efficiency.

Meet various measurement needs

Through a wide variety of measuring accessories, it is possible to flexibly measure and calibrate various ring and plug gauges, internal and external thread gauges, calibration rods, gauge blocks, dry scales, etc.

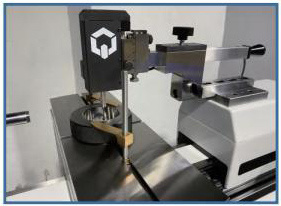

Continuously adjustable force

Adopting the new patented (patent number: 2018220145420) bidirectional force measurement technology, it can be continuously adjusted between O-12N to ensure the bidirectional force is constant during measurement and ensure stable accuracy.

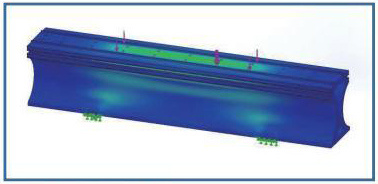

Specially designed cast iron base

The measuring base is in an X shape. After finite element calculation, this structural design reduces the error caused by deformation caused by changes in temperature, stress, etc.

Function application and examples

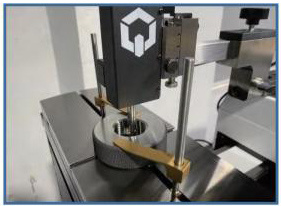

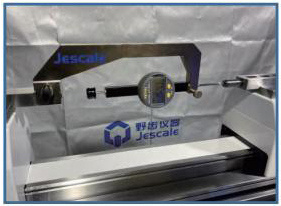

Calibration gauge block

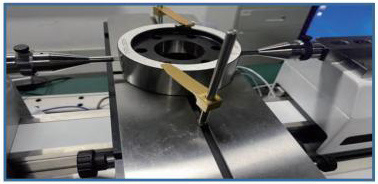

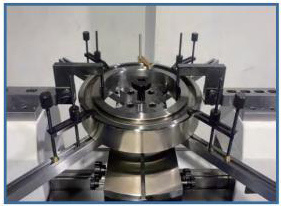

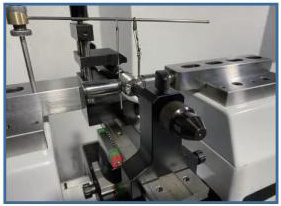

Calibration of small smooth ring gauge

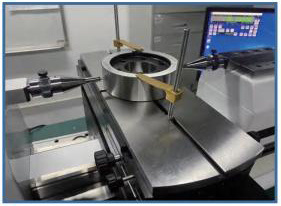

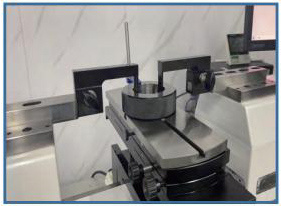

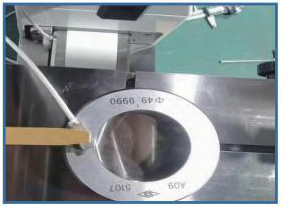

Calibration of large ring gauges

Measuring smooth plug gauge

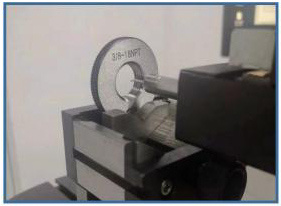

Measuring thread ring gauge

Measuring inner diameter gauge

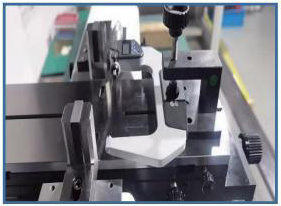

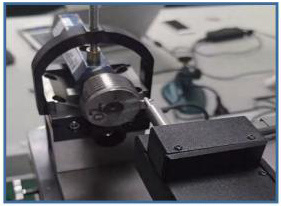

Calibration of dial indicator and micrometer

Measuring thread plug gauge

Calibration Micrometer

Calibration smooth ring gauge

Digital display table

Temperature compensation module

Calibration tapered thread ring gauge

Calibration Taper Thread Plug Gauge

Calibrate the caliper

Professional display, management and measurement software system

The basic requirement of the length gauge is to establish a connection between the length gauge and the computer system in order to monitor and measure the measured part. Software to control and analyze the test program is also very necessary. For many years, Yechi Instruments has been using self-developed measurement software. It can adapt to the usage habits of Chinese users.

U-CheckSOFT consists of a series of software modules that can run under one desktop or independently to meet the special requirements of customers.U-Check Profession

The software includes all the measuring functions of the full-length gauge. The parameters and database structure can be freely defined and managed independently on this basis. Automatic tolerance calculation can be realized on most common testing equipment, such as smooth ring plug gauges, threaded ring plug gauges, indicator gauges, bore gauges, lever gauges, calipers, micrometers, etc.

U-Check-Element1

This module integrates the calculation and evaluation of ring gauges, caliper gauges, plug gauges and micrometers. After selecting the model and specification of the measured part (for example H8), the program can automatically determine the deviation and tolerance from the normal size.

U-Check-Element2

This module includes the evaluation of various thread pitch diameters (using the two-ball method, three-ball method or three-pin method for internal and external threads) and enables efficient inspection of various types of thread gauges. The program calculates reliable results even for complex thread geometries.

U-Check-Element3

This module supports the calculation and measurement of tapered thread gauges; based on ISO7-2 and DIN2999, it supports the calculation and measurement of pipe threads; based on DIN158, it supports the calculation and measurement of tapered metric threads; based on BS21, it supports the calculation and measurement of tubular threads.

U-Check-Element4

This module is used to test dial gauges, bore gauges and lever gauges, and can meet the internal standard requirements of the user's company.

U-Check-Element5

The module supports the inspection of internal and external jaw calipers and depth calipers. The deviation of the inspection instrument is determined by comparison with the standard set points.

U-Check-Element6

This module supports the inspection of various dry scales. All parameters can be evaluated directly by the program or according to the user's own requirements.

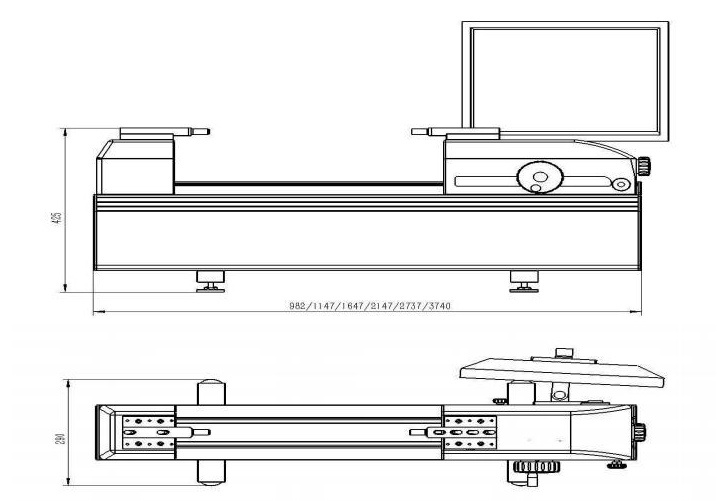

Dimensions

Technical Parameters

Technical Parameters◆ Please consult Jescale Instrument for technical details of higher precision models.

◆ The base of the UCK3000 model is marble.

RELATED PRODUCTS

Get a Free Quote

Our representative will contact you soon.